FIBER GLASS COMPOSITE REBAR

Lightweight, rust-free Fiber Glass Composite rebars engineered for durability, strength, and long-term performance.

What is FGC Rebar?

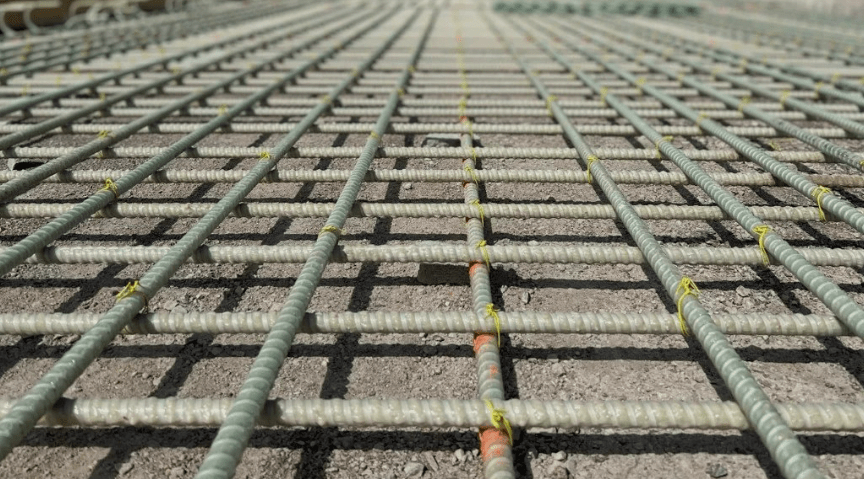

FGC Rebar (Fiber Glass Composite Rebar) is manufactured using glass fibers combined with high-grade epoxy resin, creating a strong, lightweight, and corrosion-resistant reinforcement material. Unlike traditional steel rebar, FGC rebar does not rust, making it ideal for long-term use in harsh and moisture-prone environments.

FGC REBAR BENEFITS

→ 2X Tensile Strength

→ 4X Lighter

→ 80+ Years of Life

→ Corrosion Free

→ Cost Effective

→ UV Resistant

→ All-Weather Proof

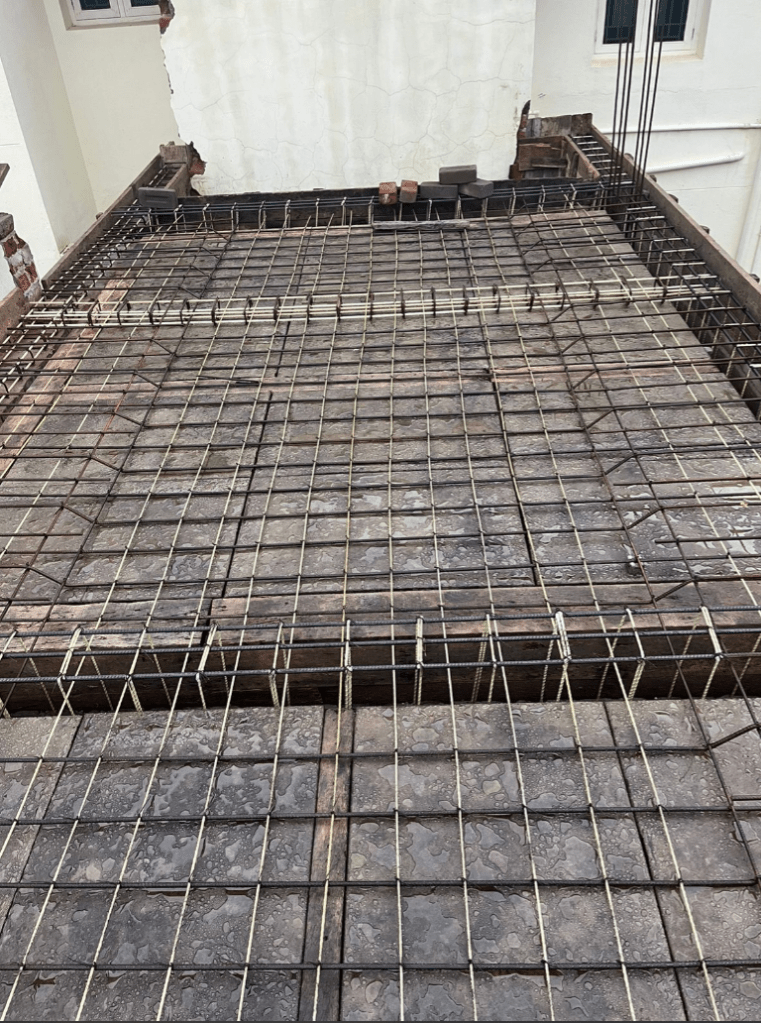

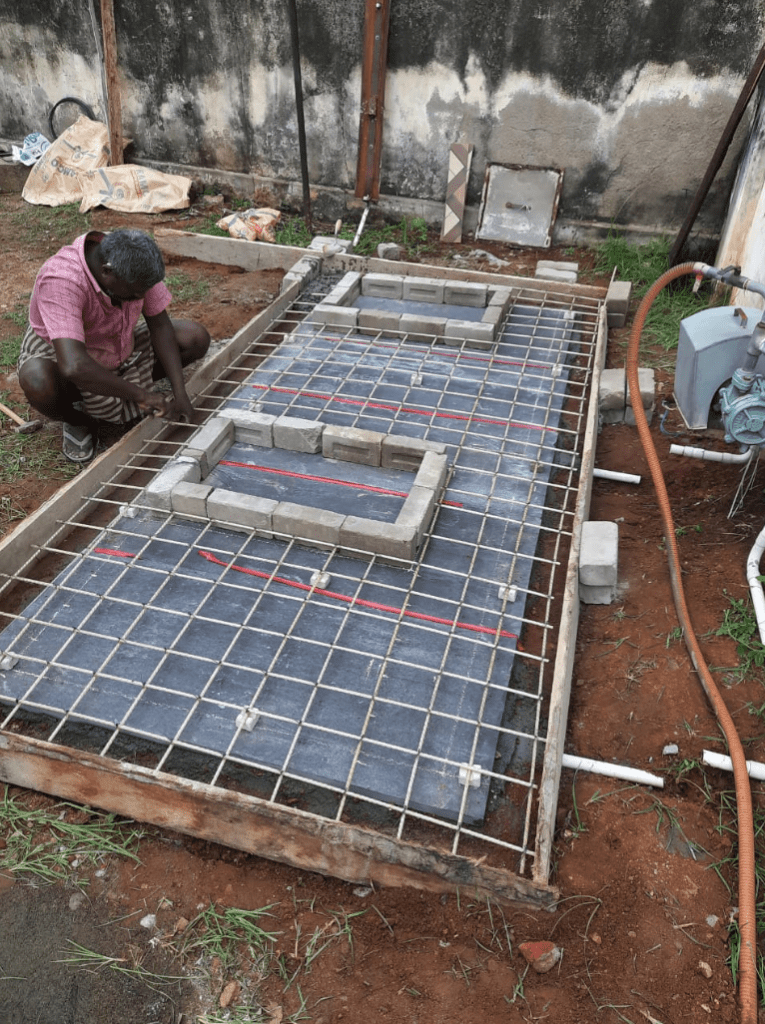

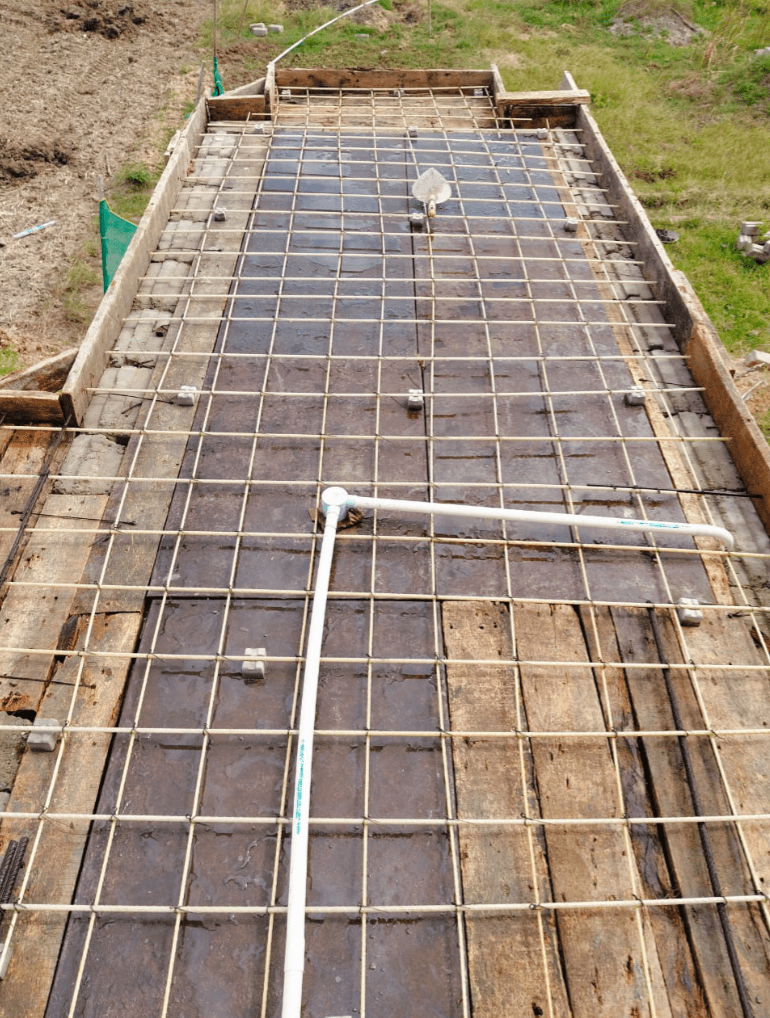

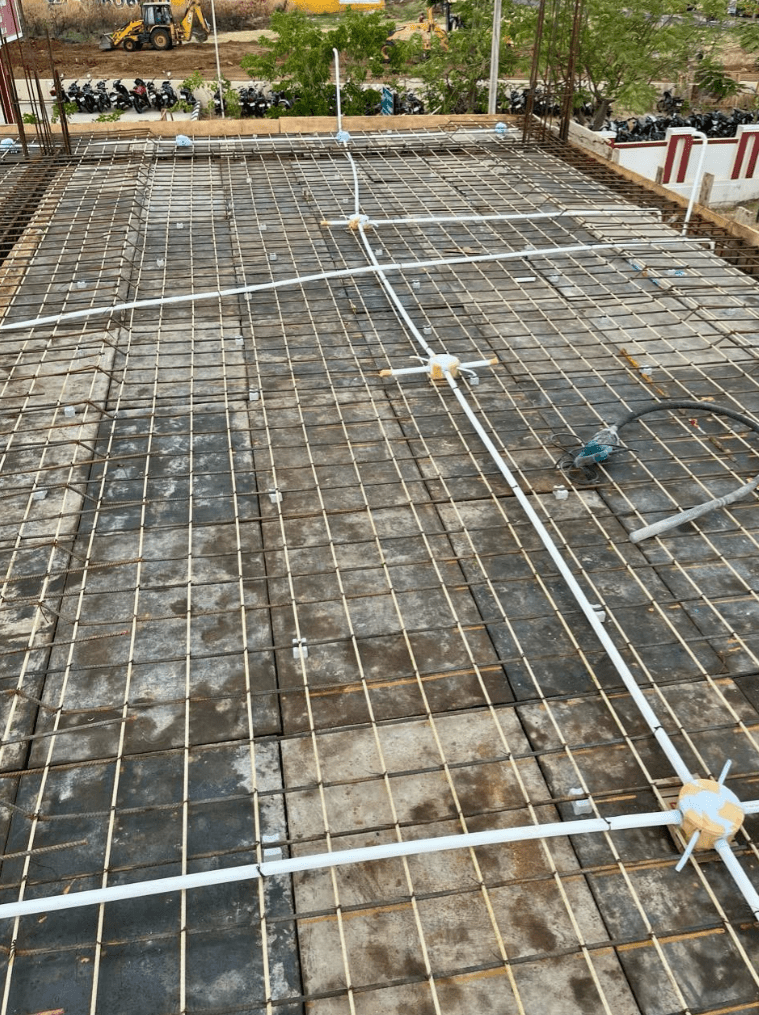

FGC REBAR USE CASES

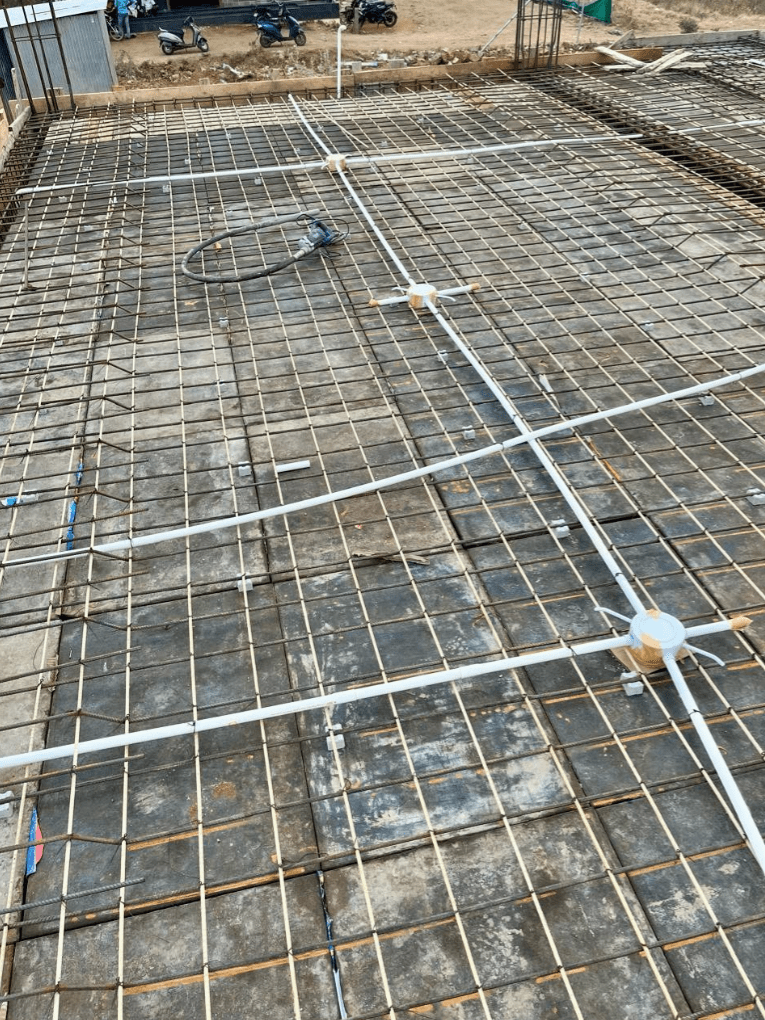

→ Reinforced Industrial Flooring

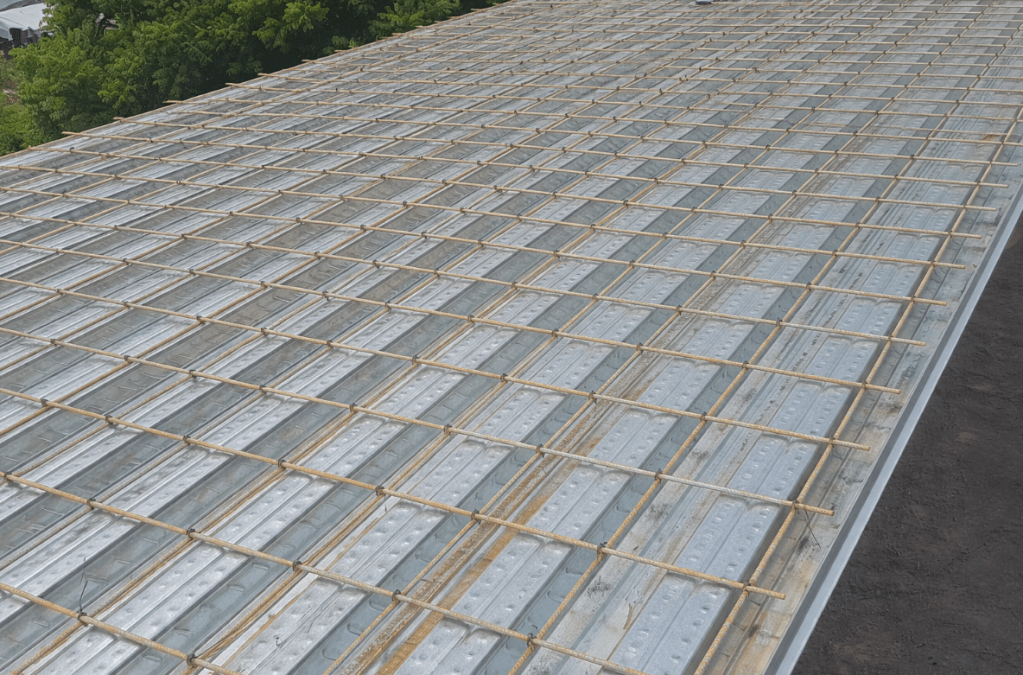

→ Deck Sheet Reinforcement

→ Road & Pavement Construction

→ Precast Concrete Products

→ Tunnels

COMPARISON TABLE

| Features | FGC Rebars | TMT Rebar |

|---|---|---|

| Tensile Strength [MPa] | 1000–1400 | 500–600 |

| Fatigue Performance | 2.5 times less cracking | Normal |

| Rusting in chemical environments | Rust Proof | Prone to Rust |

| Durability | Greater than 80 Years | As prescribed in building codes |

| Elongation [%] | 4 | 25 |

| Density [tonne/m³] | 1.9 | 7.8 |

| Eco-friendly | Yes | Yes |

| Electrical Conductivity | Insulator | Electrically Conductive |

| Work Related Injuries | Low | High |

| Patching Savings | Yes | No |

| Transport Saving | Yes | No |

| Labour saving during Installation | Yes | No |

| Custom Lengths | Any length possible | No |

| Shear Strength [MPa] | 170 | 120 |

| Bond Strength [MPa] | 12.5 | 14 |

| Compression [MPa] | 450 | 500 |

| Modulus of Elasticity [GPa] | 65 | 160–210 |

| LEED Credit Possibility | Yes | No |